What is floating bridge | Types of floating bridge | Advantages and disadvantages of floating bridge | Specification of floating bridge | Principle of floating bridge | Components of floating bridge | Limitations of floating bridge | floating bridge construction:

What is floating bridge?

Types of floating bridge: -

1. Pontoon Bridge: It consists of a series of pontoons or floating sections connected by a bridge deck. A pontoon bridge is a temporary bridge that is supported by floating pontoons or boats. These bridges are typically used to provide a temporary crossing over a body of water, such as a river or lake, where a permanent bridge is not feasible or practical. Pontoon bridges can be quickly constructed and dismantled, making them ideal for military operations, disaster relief efforts, or temporary construction projects. They have been used throughout history, dating back to ancient times, and continue to be used today in various parts of the world.

|

| Pontoon Bridge |

2. Cable-Stayed Bridge: A cable-stayed bridge is a type of bridge in which the deck is supported by cables that are attached directly to towers. The cables run from the towers to the deck at angles, providing support and stability for the structure. This design allows for longer spans and can be used for both highway and pedestrian traffic. The first cable-stayed bridge was built in Germany in the 1950s, and since then, this type of bridge has become increasingly popular worldwide due to its aesthetic appeal and structural efficiency. Notable examples of cable-stayed bridges include the Millau Viaduct in France and the Sunshine Skyway Bridge in Florida. It uses cables anchored to towers to support the bridge deck.

|

| Cable-Stayed Bridge |

3. Suspension Bridge: A suspension bridge is a type of bridge that is supported by cables suspended from towers or tall pillars. The cables are anchored to the ground or to massive concrete blocks at each end of the bridge. The weight of the bridge and the traffic it carries is transferred to the cables and then to the supports.

The deck, or roadway, of the bridge hangs from the cables and is made of steel or concrete. The deck is supported at intervals by vertical cables, which are also attached to the main cables. The design of a suspension bridge allows it to span longer distances than other types of bridges, making them an ideal choice for crossing deep valleys and waterways.

Famous examples of suspension bridges include the Golden Gate Bridge in San Francisco, California, the Brooklyn Bridge in New York City, and the Akashi Kaikyo Bridge in Japan, which is currently the longest suspension bridge in the world with a main span of 1,991 meters (6,532 ft). It uses cables suspended between towers to support the bridge deck.

|

| Suspension Bridge |

4. Barge Bridge: Barge Bridge is a type of bridge designed to allow boats and barges to pass underneath it. These bridges are also called "lift bridges" because they raise up in a vertical motion to provide clearance for the passing vessels. Barge bridges are commonly found over waterways that have a lot of boat traffic, such as canals and rivers.

One prominent example of a Barge Bridge is the Tower Bridge in London, which is a drawbridge that lifts its two massive towers to allow boats to pass through the River Thames. Another example is the Queen Emma Bridge in Willemstad, Curacao - a swinging pedestrian bridge that swings open to let ships and barges through.

Barge Bridges have also gained popularity as a structural design element in urban architecture, as they add a unique element and become landmarks in their own right.

|

| Barge Bridge |

5. Foldable Truss Bridge: A foldable truss bridge is a type of bridge that is designed to be easily dismantled and transported to different locations. The bridge is typically made up of triangular sections, which provide the necessary strength and stability to span a gap or river.

One example of a foldable truss bridge is the Bailey bridge, which was first developed by the British during World War II. The Bailey bridge consists of prefabricated steel panels that are bolted together to form a truss structure. The bridge can be built in a matter of days and can support heavy loads, making it ideal for military use.

Another example of a foldable truss bridge is the Mabey Compact 200, which is widely used for emergency and temporary bridge applications. The Compact 200 is similar to the Bailey bridge in design, but has a lighter weight and smaller footprint, making it easier to transport and assemble.

Foldable truss bridges have a number of advantages over traditional fixed bridges. They can be customized to fit the specific needs of a particular site, and can be quickly erected in emergency situations. They are also more cost-effective than permanent bridges and can be reused in different locations.

|

| Foldable Truss Bridge |

6. Floating Drawbridge: A floating drawbridge is a type of bridge that is designed to be raised and lowered to allow boats, ships, or other watercraft to pass under the bridge. Unlike traditional drawbridges that are fixed to the ground, floating drawbridges are anchored in place and use a system of cables, pulleys, and counterweights to raise and lower the bridge deck.

Typically, floating drawbridges are found in areas with high water traffic, such as harbors, rivers, or canals. They are particularly useful for ensuring that boats and ships of all sizes can pass under the bridge without issue. While floating drawbridges may require more maintenance than traditional drawbridges, they are often seen as a more efficient and cost-effective solution for areas with a lot of water traffic.

Overall, floating drawbridges are an innovative and important type of infrastructure that help to keep our waterways and transportation systems flowing smoothly.

|

| Floating Drawbridge |

7. Trestle Bridge: A trestle bridge is a type of bridge that uses a series of short, closely spaced spans to support the weight of the bridge deck. These short spans are typically made of timber or steel beams and are supported by piers or abutments. Trestle bridges are commonly used in areas with uneven terrain or in areas where traditional bridge designs would be too expensive or difficult to construct. They are also used in mining and logging operations to transport heavy equipment and materials across difficult terrain. One of the most famous trestle bridges is the Kinzua Viaduct in Pennsylvania, which was one of the tallest and longest railroad bridges in the world when it was first built in 1882.

|

| Trestle Bridge |

8. Self-propelled Bridge: A self-propelled bridge is a type of bridge that can move independently from one location to another without the need for external forces or towing vehicles. These bridges typically have an embedded power source and a propulsion system that allows them to navigate through various terrains and environments, such as crossing rivers, valleys, or rough terrain.

Self-propelled bridges are commonly used in military operations, disaster relief efforts, and in construction and maintenance projects where a temporary, movable bridge is needed. They can be designed to accommodate various types of vehicles and loads, and some models even feature advanced safety and navigation systems to ensure smooth and secure transportation.

Self-propelled bridges have several advantages over traditional, fixed structures. For example, they are highly versatile and can be easily relocated to new areas as needed. They also require less time and resources for installation and removal, which can save money and reduce disruption to local communities. Additionally, self-propelled bridges can provide a temporary solution for situations where permanent infrastructure is not feasible or cost-effective.

|

| Self-propelled Bridge |

Advantages and disadvantages of floating bridge: -

Advantages:

1. Flexibility: Unlike fixed bridges, floating bridges can be moved and adjusted according to changing water levels or water flow. This means they can be used in areas where fixed bridges would be impossible to construct.

2. Cost-effective: Floating bridges are generally cheaper to build than fixed bridges. This is because they require less maintenance and are easier to construct.

3. Easy installation: Floating bridges can be installed quickly and easily, making them ideal for emergency situations.

4. Minimal environmental impact: Floating bridges have a smaller environmental impact than fixed bridges. They do not require pillars or supports to be driven into the riverbed, which can disrupt the natural ecosystem.

Disadvantages:

1. Limited capacity: Compared to fixed bridges, floating bridges have a lower weight capacity. This means they can only support lighter vehicles and cannot accommodate heavy-duty transportation.

2. Vulnerable to weather: Floating bridges are more susceptible to damage from severe weather conditions. High winds, heavy rain, and storm surges can cause significant damage, resulting in operational downtime.

3. Maintenance challenges: Floating bridges require regular maintenance to ensure their structural integrity. This can be challenging, as maintenance teams must access the bridge while it is floating on water.

4. Navigation hazards: Floating bridges can pose a navigation hazard for boats and other watercraft. They can obstruct waterways and may require additional safety measures to prevent collisions.

Specification of floating bridge: -

here is specification of a floating bridge:

1. Dimensions: The length, width, and height of the bridge must be determined based on the waterway's size, depth, and current conditions. The bridge must be stable and able to withstand strong waves and wind.

2. Material: The floating bridge can be made of different materials such as steel, aluminum, concrete, composite materials, or a combination of them. The material choice must consider factors such as durability, weight, and resistance to corrosion and rust.

3. Anchoring System: The floating bridge must be anchored to the shore or to the riverbed using cables, ropes, or pillars. The anchoring system must be robust and flexible enough to withstand water currents and water flow changes.

4. Decking: The deck surface of the bridge can be made of wood, concrete, or a specialized anti-slip coating. The surface must be suitable for pedestrian and vehicle traffic, and must not be too slippery or too rough.

5. Lighting: The bridge must have adequate lighting for nighttime use and visibility. Lighting can be integrated into the bridge structure or installed as separate fixtures.

6. Safety Features: The floating bridge must have proper safety features such as railings, barriers, and warning signs to prevent accidents and mishaps.

7. Accessibility: The bridge must be accessible to pedestrians, cyclists, and vehicles, and must comply with accessibility guidelines and regulations.

8. Maintenance: The bridge must be designed for easy maintenance and repair, and regular inspections must be carried out to ensure its safety and longevity.

Principle of floating bridge: -

The principle of a floating bridge is based on the principle of buoyancy, which states that an object will float if the weight of the water it displaces equals its own weight. In a floating bridge, the weight of the bridge is distributed evenly across its surface area, creating enough buoyancy to keep the bridge afloat.

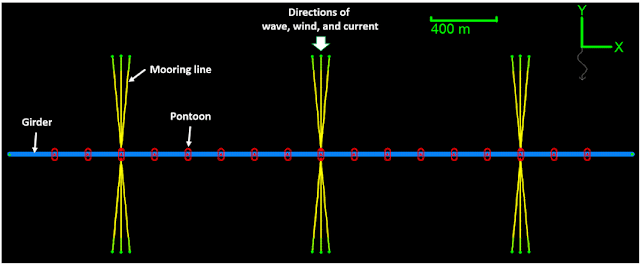

The floating bridge is usually made of pontoons, which are hollow structures that can be filled with air or water. The pontoons are connected together using a strong support system and are anchored to the shore by cables or chains. The bridge deck is attached to the top of the pontoons, creating a stable surface for vehicles and pedestrians to cross.

The buoyancy of the floating bridge allows it to adjust to changes in water level, ensuring that it remains stable even during tidal fluctuations or river flow changes. The floating bridge can also accommodate the movement of boats and ships, as it can be designed to lift or pivot to allow for their passage.

Overall, the principle of a floating bridge is based on the ability of a structure to float on water by utilizing the buoyancy force, making it a versatile and practical solution for crossing bodies of water.

Components of floating bridge: -

1. Floating pontoons: These are the main components of a floating bridge. They are large, hollow structures that provide buoyancy to the bridge.

|

| Floating pontoons |

2. Anchor system: The anchor system secures the bridge in place and prevents it from drifting away. Anchors are set at specific intervals along the bridge and are attached to the pontoons.

|

| Anchor system |

3. Bridge deck: The flat surface that covers the pontoons is called the bridge deck. It provides a stable platform for vehicles and pedestrians to cross.

|

| Bridge deck |

4. Handrails: Handrails are installed on both sides of the bridge deck to ensure the safety of pedestrians and vehicles.

|

| Handrails |

5. Ramp system: The ramp system connects the bridge to the shore and provides easy access for vehicles and pedestrians.

|

| Ramp system |

6. Mooring system: Mooring lines are attached to the bridge and secured to the shore to keep it in place during heavy winds or currents.

|

| Mooring system |

7. Lighting system: The lighting system is installed on the bridge deck and provides illumination for safe navigation during the night.

|

| Lighting system |

8. Navigation aids: Navigation aids such as buoys and markers are placed around the bridge to guide ships and boats around it.

Limitations of floating bridge: -

1. Limited water depth: Floating bridges are limited by the water depth they can accommodate. If the water depth is too shallow or too deep, a floating bridge may not be suitable for use.

2. Weather conditions: Floating bridges are also limited by the weather conditions that they can withstand. Strong winds, heavy rains, and rough waters can affect the stability of a floating bridge and make it unsafe for use.

3. Maintenance: Floating bridges require regular maintenance to ensure their stability and safety. This can be a costly and time-consuming process, and maintenance may need to be performed more frequently than with other types of bridges.

4. Load capacity: Floating bridges have a limited load capacity, which can restrict the types of vehicles and equipment that can be transported across them. In some cases, this may require vehicles and equipment to be modified or transported by alternative means.

5. Navigation: Floating bridges can also be challenging to navigate for larger vessels, such as cargo ships or cruise liners. This can limit the accessibility of certain waterways and ports that are located near floating bridges.

Floating bridge construction: -

Floating bridges are complex engineering structures that are constructed to provide temporary or permanent crossing over water bodies. The construction process consists of several stages, including planning, design, site preparation, and implementation.

1. Planning: The first step in constructing a floating bridge is planning. This involves identifying the location where the bridge will be built, evaluating the environmental and topographical considerations, determining the purpose of the bridge, and estimating the expected traffic volume.

2. Design: The second step involves designing the bridge, taking into account the expected load capacity, length, and width. The design process also includes selecting the appropriate materials, such as steel, timber, or concrete, and determining the buoyancy requirements based on the water depth.

3. Site Preparation: The third step in building a floating bridge is site preparation. This typically involves clearing the land of vegetation and leveling the ground. Additionally, temporary access roads may need to be built to provide access to the construction site.

4. Implementation: The actual construction work begins with the installation of the floating pontoons, which are typically made of steel or concrete. The pontoons are anchored to the seabed using mooring systems, such as piles or anchors. Once in place, the pontoons are connected by stringers and decking to create the bridge surface.

5. Finishing: After the bridge has been constructed, finishing work is carried out, which includes installing any necessary safety equipment, such as guardrails and lighting systems. The bridge can then be tested to ensure that it is safe for public use.

Overall, the construction of a floating bridge is a complex and challenging process, requiring careful planning, design, and implementation to ensure that the resulting structure is safe and functional.

Comments

Post a Comment